Thermal Flow Meter Calibration Gas Service

Background

This case study looks at the importance of gas composition and calibration and their effects on flow meter accuracy for an North American manufacturer.

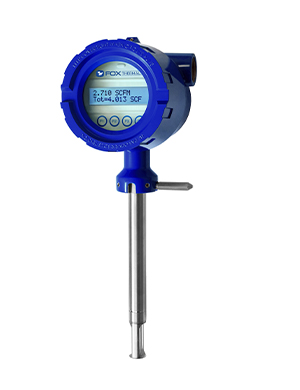

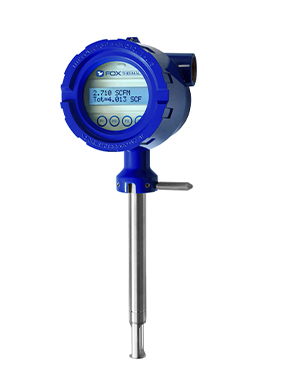

Pipeline sizes in these applications ranging from 1.5 to 8 inches and a preference for installation without shutting down the pipelines suggested applying insertion flow meters. The desire to measure gas flow accurately over a wide range of flow rates without the need for pressure and/ or temperature compensation suggested the application of thermal mass flow meter technology. Therefore, the insertion of thermal mass flow meters were selected to measure natural gas flows in the odorisation systems.

Challenge

Inaccuracies in accordance with the calibration of flow meters for natural gas service can be costly but it’s possible to diminish this expense. By employing an advanced flow meter design that allows field-adjustment of the natural gas composition, costs are saved and without the loss of performance or precision.

Solution

The existing flow meters were configured for a natural gas composition similar to the North American Energy Standards Board’s (NAESB) typical analysis and calibrated using the factory-standard surrogate natural gas.

In this example, the manufacturer used the actual natural gas compositions to perform calculations that confirmed the flow measurement errors were similar to those experienced by the transporter. The standard approach to rectify this problem would be to return the flow meters to the factory for recalibration with various surrogate gases representative of the various natural gas streams. This was not admissible by the transporter in the short term and would have made compensating for future composition cumbersome in the long term.

However, the existing flow meters were factory-calibrated in a well- defined gas, to which correlations were used to measure natural gas using the alternative method previously described. Using this technology, each component in the natural gas could be configured in 0.1-percent increments in the field to measure the flowing natural gas with no loss of accuracy.

Result

For new installations, users should include their natural analysis specifications and strongly consider purchasing flow meters that are calibrated with a well-defined gas in the factory. This allows the actual flowing natural gas composition to be set in the field with no loss of accuracy.

Huge financial losses can occur in some applications when natural gas flow meters are not precise enough. Conversely, large cost savings can be realised when the performance of existing flow meters are inspected and corrected.